The process and its advantages

Plasma nitriding is a heat treatment process in which the edge layer of a workpiece is converted chemically. During this process, nitrogen penetrates the material and forms nitrides. Plasma nitriding and plasma nitrocarburising deliver reliably reproducible outcomes and are superior to other nitriding processes - especially in terms of environmental protection and energy consumption. The process requires no toxic gases, and the energy consumption is reduced substantially.

This is partially because the hardening process is carried out at low temperatures between 350 and 600°C. Warping of the workpieces is also reduced to a minimum, eliminating the need for costly rework, and thus delivering additional cost savings.

Furthermore, plasma nitriding considerably improves a number of workpiece properties, such as service life, corrosion protection, and resistance to fatigue and wear. A partial treatment is also unproblematic. The process is also suitable for subsequent physical and chemical vapour deposition with individual hardness properties, because if necessary a diffusion layer can be created without a compound layer on the surface of the workpiece.

The process is also known by the names of ionitriding, pulse plasma nitriding, cold nitriding, or plasma hardening.

INFO: HLX-1 – process for special surface protection

HLX-1 is defined as a diffusion process that specifically treats the surfaces of components and tools. HLX-1 creates a protective layer that is ideally suited for structured and polished surfaces. In addition, warping is extremely low.

The advantages of plasma nitriding at a glance

- Improved protection against wear and corrosion

- Excellent vibration resistance

- Fewer brittle and porous layers compared with salt bath nitriding and gas nitriding

- Adaptable layer structure

- Minimum warping thanks to low process temperature, so reworking of components is unnecessary

- Partial hardening possible by applying a protective compound or using mechanical means

- No post-cleaning necessary, because the components receive final cleaning and surface activation in the plasma

- Short treatment times compared with gas nitriding

- Alloy steels and stainless steel can be treated with good results

The physical basis

Plasma nitriding takes place in a vacuum. An electric field is applied during the process. The workpieces act as the cathode, and the furnace wall is the anode. The added mixture of gas is ionised by the electric field and it envelops the workpieces. The process creates nitrogen-rich nitrides, which disintegrate and enrich the surface with nitrogen.

The surface is activated, and the workpieces are heated. On steels such as stainless steel, the passive layers detach. Generally speaking, the surface receives fine cleaning, because the process sputters off impurity atoms.

The treatment temperature depends on the material type and the desired nitriding hardness depth. The subsequent dwell time ranges between 12 and 50 hours. To equalise the pressure when the treatment is complete, the furnace is flooded with gas. The workpieces cool down.

the process and its advantages

Plasma nitriding ranks among the most flexible and best nitriding processes. It is generally suited for any type of iron material, but the benefits of the treatment vary with the material.

- Construction steel: greater protection against wear and corrosion

- Sintered materials: Operating characteristics and wear protection are improved despite porosity

- Alloy steels (with a high chromium and aluminium content): particularly improves components subjected to great strain

- Stainless steel: Wear protection thanks to standard processes with maximum hardness and nitriding hardness depth. Alternative options are long-term, low-temperature processes for high corrosion protection with great surface hardness

Typical components

- Gear shafts, crankshafts and cam shafts

- Cam followers

- Valve components

- Extruder screws

- Die cast tools

- Forging dies

- Tools for cold forming

- Injection nozzles

- Plastic injection moulding tools

- Long shafts

- Axles

- Couplings and engine parts

The nitrided layer and its properties

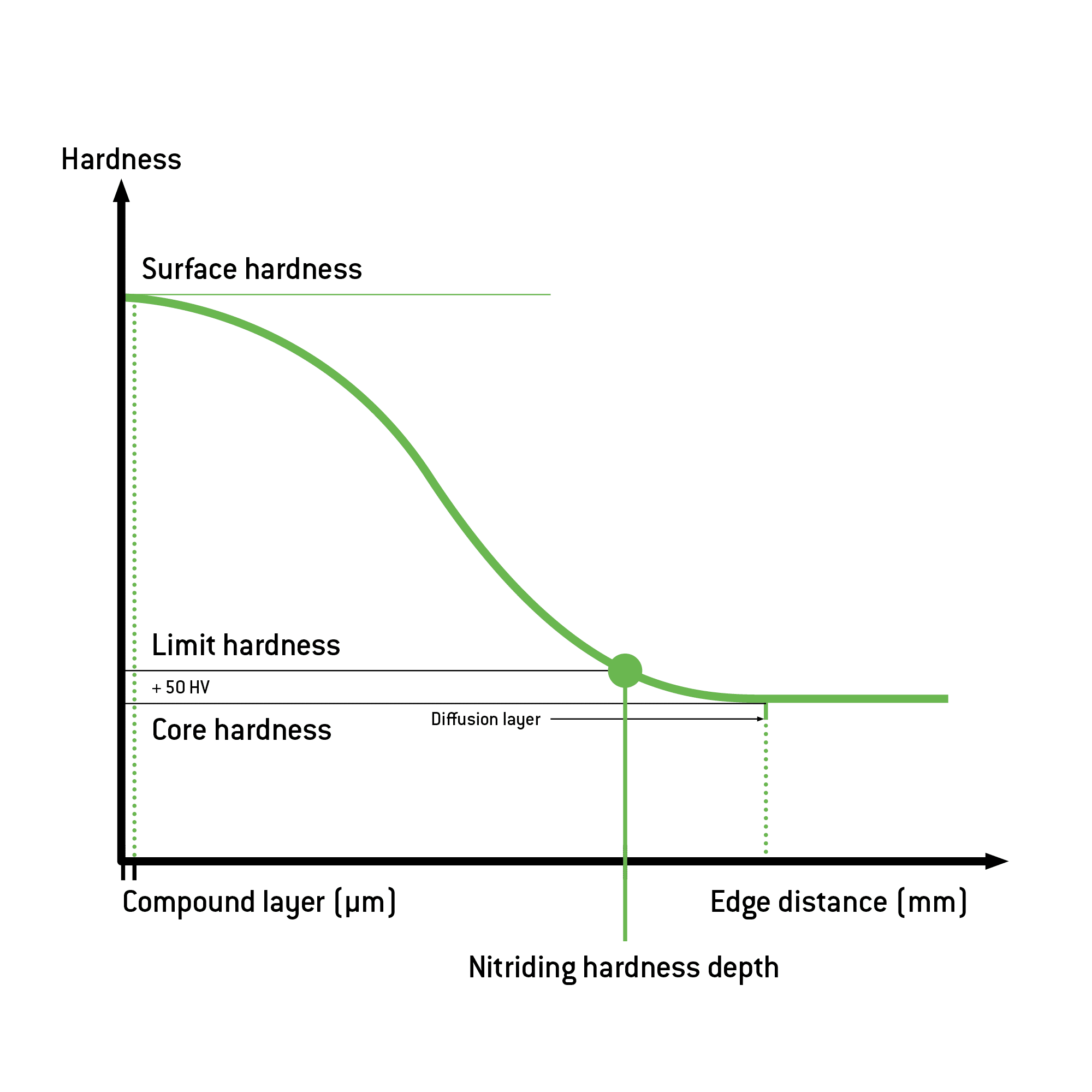

On the surface, the nitrided layer consists of the compound layer. It is composed of iron nitrides and is more compact and less porous compared with gas nitriding. This layer is followed by the diffusion zone, which is composed of the material and the precipitated nitrides.

If nitriding steel or high-alloy steel with many nitride-forming elements is used, the surface hardness that can be attained also increases accordingly (up to 800–1,200 HV compared to 250-300 HV for non-alloy and 600-700 HV for low-alloy steel). The edge distance having a core hardness of +50 HV is considered to be the characteristic value of the nitriding hardness depth (NHD). This is up to 0.6 mm for non-alloy and low-alloy steels and up to 0.10 / 0.15 mm for high-alloy steels and stainless steel. Influencing factors are the steel used, along with the duration and the temperature of the treatment.

There are variations and enhancements of plasma nitriding, and their use depends on the requirements:

- Plasma nitrocarburising: for particularly thick compound layers

- Post-oxidation: further increases corrosion protection on low- and medium-alloy materials

Nitridable steels and treatment outcomes after plasma nitriding

The following results illustrate the effect of plasma nitriding on frequently used materials. Standard and long-term treatments were used. A higher or lower nitriding hardness depth (NHD) and compound layer thickness (CLT) can be achieved by special treatments.