General information on the edge layer hardening of steel

Edge layer hardening designates the partial hardening of metal components in their edge layer. The process is synonymous with surface hardening. The surface is heated to its austenitising temperature and then quenched. The core remains largely unaffected by this procedure.

The process creates various layers with different properties in the workpiece – the tough primary material in the core, and the hardened surface with significantly greater wear resistance. This combination of properties is ideal for components subjected to great mechanical strain, such as gear wheels and presses.

Edge layer hardening involves hardening by austenitising followed by a subsequent formation of martensite, i.e. a change of the microstructure. In contrast, nitriding does not result in a change of the microstructure, but in a chemical change in the edge layer.

Technical details

Only quenched and tempered steel with a carbon content of at least 0.45% is well suited for edge layer hardening, as this process involves no external supply of carbon. As a general rule, the hardenability of steels depends on their carbon content. This content can be increased by carburising.

The appropriate temperature for edge layer hardening depends on the material. It is 50 to 100 °C higher than the hardening temperature of the respective steel grade. The material is heated by induction, laser beam, electron beam, or flame.

To reduce stresses and brittleness, hardening can be followed up with annealing or tempering. These steps make it possible to regulate individual parameters for the workpiece.

The advantages at a glance

Steels subjected to edge layer hardening provide a number of attractive benefits:

- Their general durability and fatigue strength increase, because the component becomes more resistant to wear.

- Residual compressive stresses and tensions increase the vibration resistance of the component surface.

- The rigidity and resilience of the use surfaces are improved by the increased surface hardness (which is important, for instance, for the rolling surfaces of gear wheels).

- In addition, subsequent grinding can provide even greater precision and higher surface quality.

Process for hardening the surface of steels

Edge layer hardening process without changing the chemical composition

Induction hardening/inductive hardening

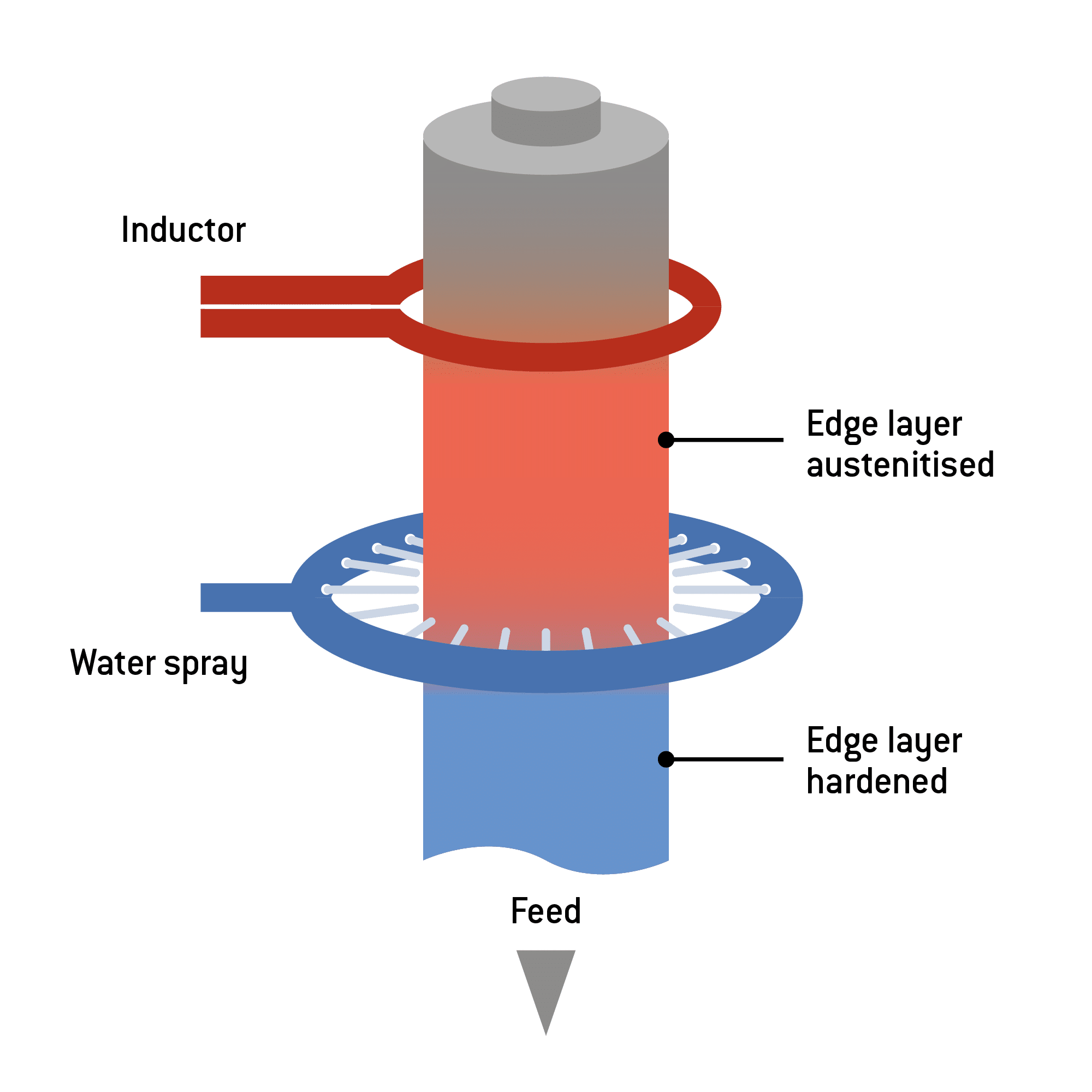

The basic principle behind induction heating is the heating of the workpiece surface using alternating magnetic fields. The hardening takes place during the subsequent quenching process. Inductive hardening is an excellent option for the mass production of components, because it is ideally suited for automation and high throughput.

Process: Inductive hardening

Edge layer hardening is a standard process at Härtha. What sets our process apart is the inductive hardening. We will be happy to advise you on hardening processes that fulfil your specific requirements.

Laser and electron beam hardening

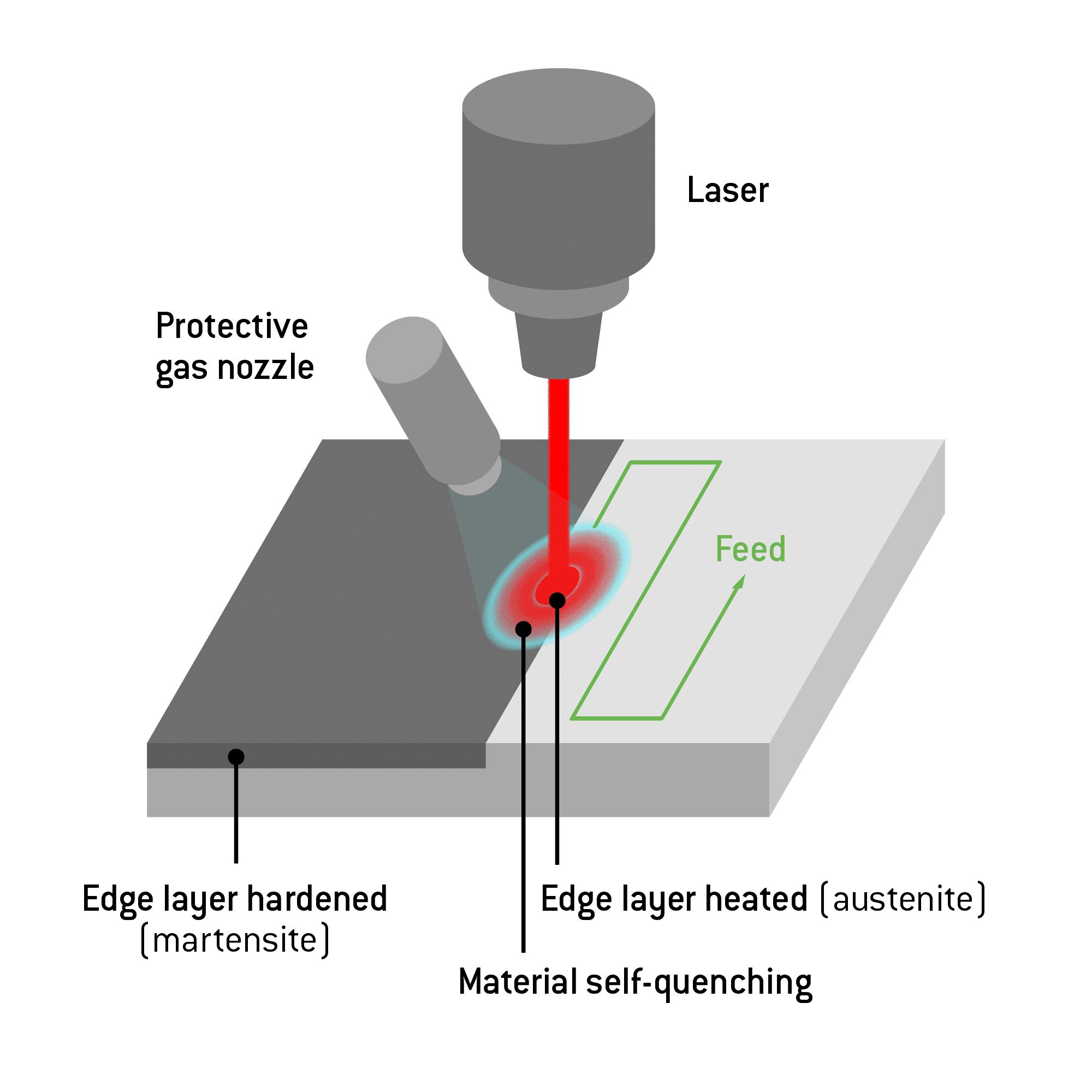

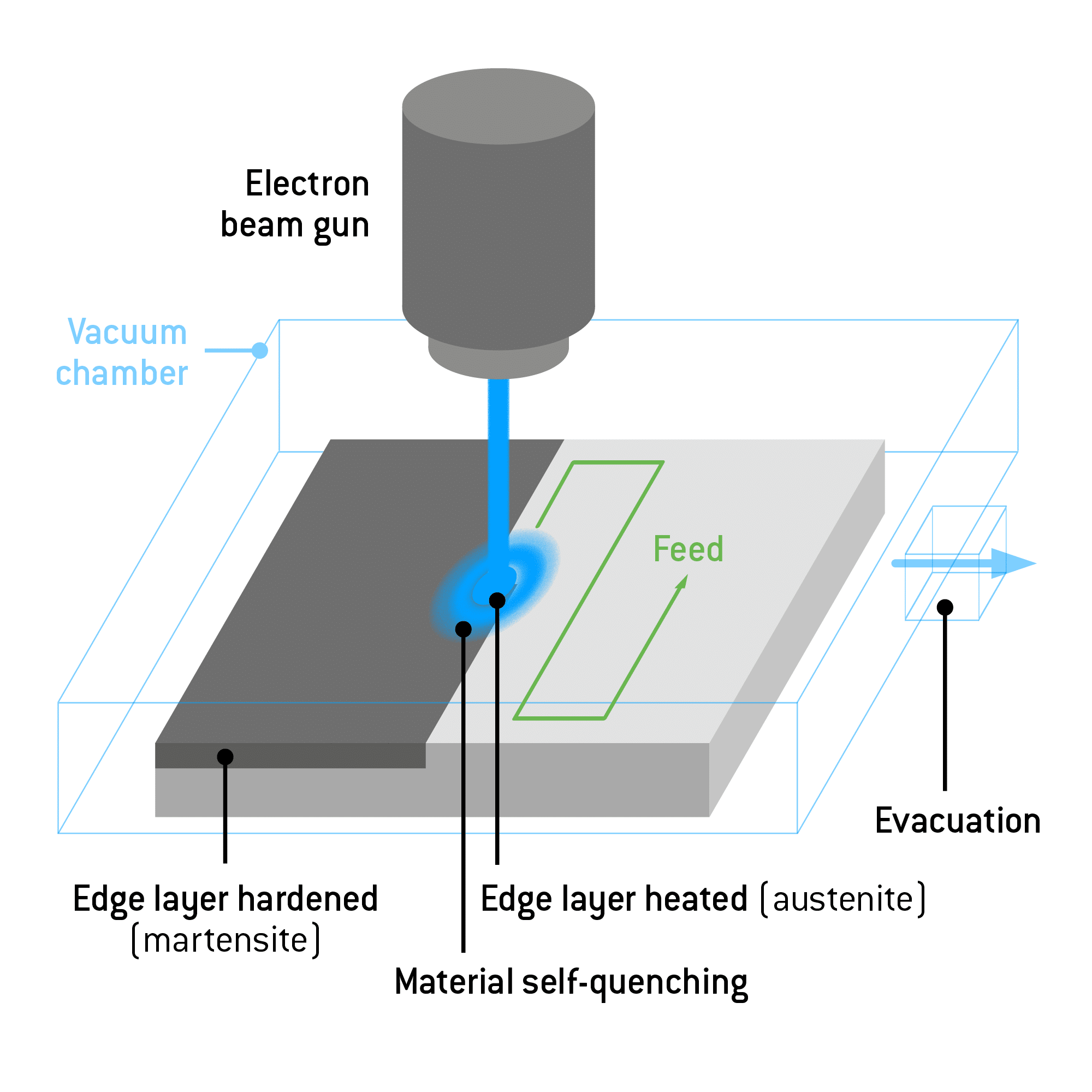

Electron beam and laser beam hardening are particularly well suited for small workpiecesthat require only shallow hardening depths.

Both laser beams and electron beams can be used to heat the steel surface until it reaches its austenitising temperature - by means of point-by-point or plane heating. Heating with laser beams or electron beams is very fast. The rapid speed facilitates quenching, which takes place almost by itself through the slow heat conduction.

Caption: Process: Laser hardening

Process: Electron beam hardening

Thermochemical diffusion treatment with change of chemical composition

Hardening of the edge layer by carburising using carbon and subsequent hardening and tempering

Hardening of the edge layer with nitrogen feed

Hardening of the edge layer with carbon and nitrogen supply, and subsequent hardening and tempering

Hardening of the edge layer in a vacuum furnace with hydrocarbon