ALDOX - nitrocarburising with post-oxidation

ALDOX offers exceptionally high corrosion resistance and gives your workpieces a refined surface ranging from anthracite to black. It is an environmentally friendly alternative to the usual corrosion protection processes such as nickel plating, chrome plating or salt bath nitriding.

We use ALDOX for components that need to satisfy the most demanding technical requirements - whether as a single part, in custom sizes or as batch production parts. We are happy to be at your disposal for a personal, no-obligation consultation that will help us meet your individual requirements in the best possible way.

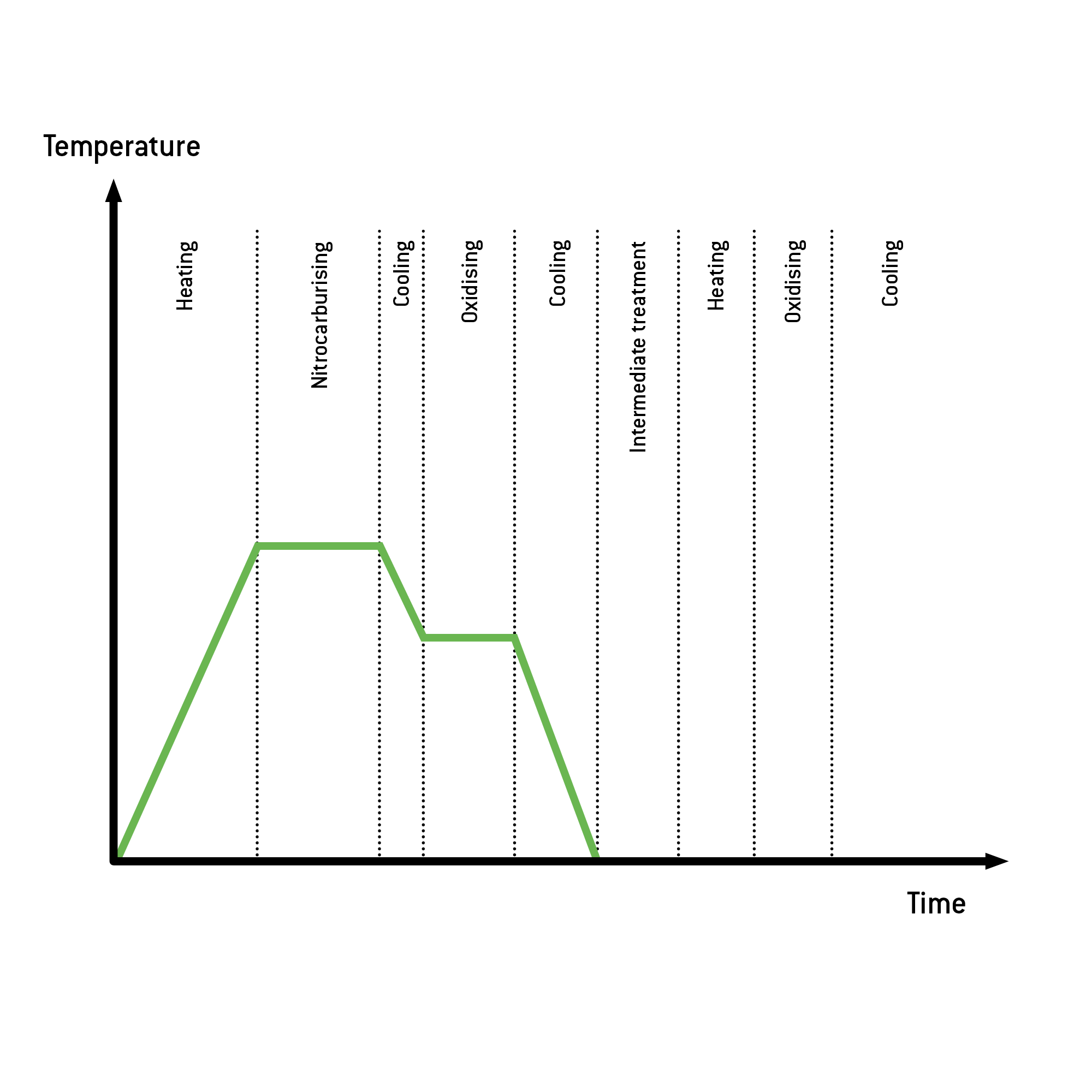

ALDOX-S in detail

Der Prozessablauf beim ALDOX-S-Verfahren ist nahezu identisch mit dem NIOX-Verfahren. Wir haben aber Parameter wie Temperatur, Gaszusammensetzung und Schichtaufbau angepasst, um im Salzsprühnebeltest ein optimales Ergebnis zu erzielen. So wird zum Beispiel nach dem Nitrieren die Temperatur auf Oxidiertemperatur abgesenkt.

Auf diese Weise entsteht an der Bauteiloberfläche eine 0,5 bis 2 μm dicke, dichte Oxidschicht aus Eisenoxid Fe3O4. Die Kombination aus der Nitrierschicht (Verbindungsschicht) und Oxidschicht bestimmt maßgeblich die Verbesserung der Korrosionsbeständigkeit.

Process flow ALDOX-S

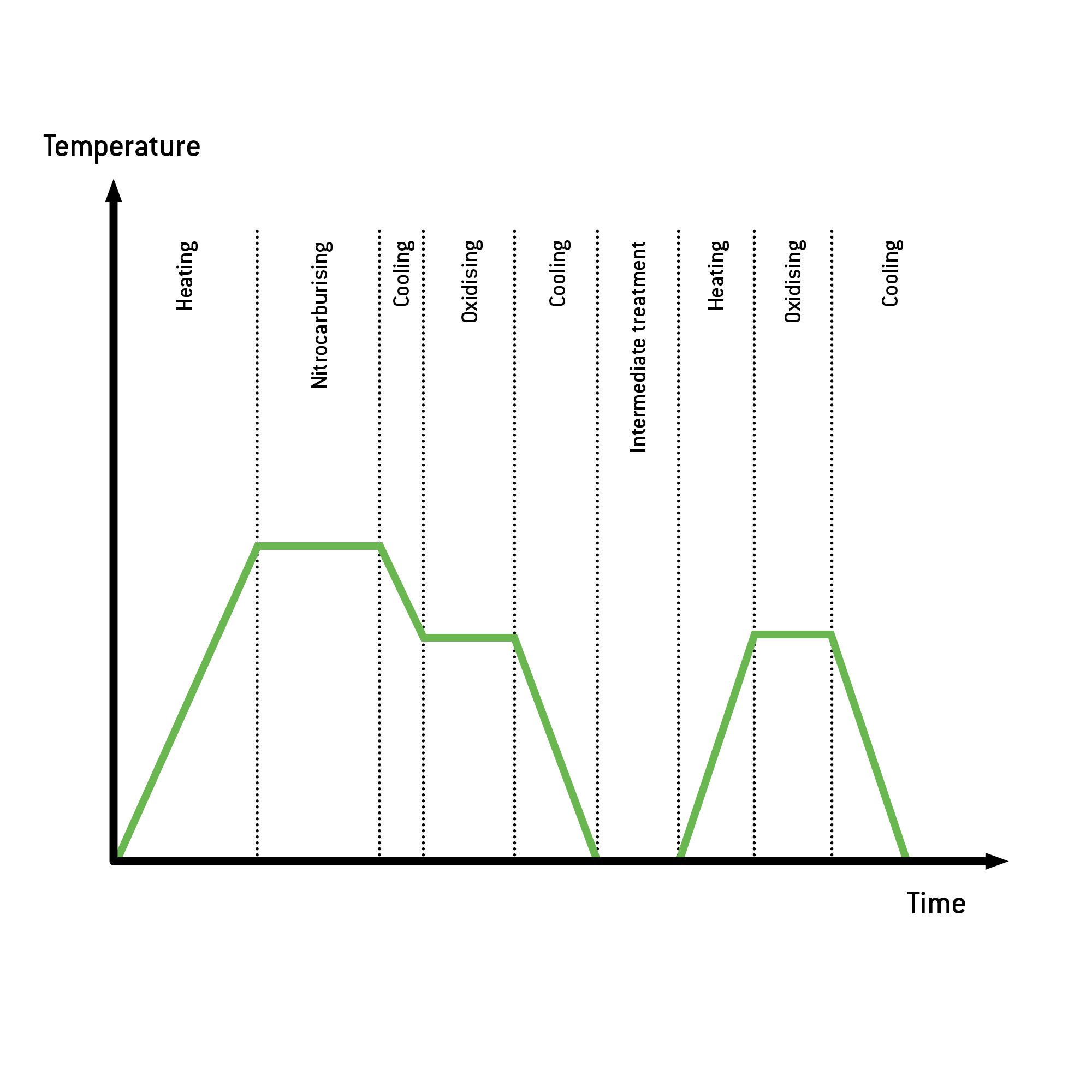

ALDOX-P in detail

ALDOX-P is distinguished from ALDOX-S by the addition of an intermediate treatment and another oxidation process. This results in the creation of a component surface with anoxide layer composed of iron oxide Fe3O4 that is 1 to 3 µm thick and offers excellent adhesion.The combination of the nitrided layer, acting as a compound layer, with this oxide layer leads to significantly improved corrosion resistance in the treated workpiece.

Intermediate treatment & additional oxidation process:

The optimized nitrocarburising is followed up with a post-oxidation of the workpieces . In this step, the compound layer produced in the preceding step is partially converted into an oxide layer by dwelling and cooling in an oxidising environment. The process concludes with another complete oxidation process (heating, oxidising, and cooling). This lends an additional oxide layer to the workpieces.

Process flow ALDOX-P

Advantages of the ALDOX process

- Greater surface hardness

- Improved resistance to corrosion

- Increase in wear resistance

- Excellent friction and sliding properties

- High reproducibility

- Attractive dark grey to black colour

- Environmentally friendly method

- Only minimum increase in surface roughness

- Great dimensional stability

- Dimensional changes resulting from manufacturing can be factored in

INFO: Corrosion resistance

The resistance to corrosion depends on various factors, such as the material used, the surface roughness, possible impurities and the geometry of the component. For many materials, ALDOX-S and ALDOX-P exceed the requirements commonly imposed on corrosion resistance. This has been confirmed by a salt mist spray test according to DIN EN ISO 9227 NSS:2017-07.

the process and its advantages

The ALDOX processes allow for the treatment of a wide range of materials, including non-alloy and low-alloy steels, tool steels, cast materials and sintered iron. The treated workpieces are perfect for use in the automotive industry as well as in areas of mechanical and plant engineering.